SWI Bellows Seal Valves Design Features

SWI Bellows Seal Valve General Design & Wall Thickness :

Forged Gate Valves – API 602 / ASME B16.34 / ISO 15761

Forged Globe Valves – API 602 / ASME B16.34 / BS5352 / ISO 15761

Cast Gate Valves – API 600 / ASME B16.34 / ISO 10434

Cast Globe Valves – API 600 / ASME B16.34 / BS1873

Bellows Inspection & Test : MSS SP-117 / API 602

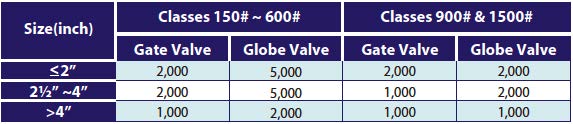

Cycle Life for Class 1500 Forged Valves and all Classes of Cast Valve :

– As per MSS SP-117

– Min. 10,000 Cycles for Globe Valves

– Min. 2,000 Cycles for Gate Valves

Cycle Life for Class 1500 Forged Valves and all Classes of Cast Valve :

– As per MSS SP-117

Cycle Life Test : Is performed under the maximum pressure condition.

Non-Rotating stem : Prevents torsion of bellows.

Two Secondary Stem Seals : Stem backseat and stem packing ensure the perfect sealing in the event of bellows damage.

Long Life Seating Surface : Stellite 6 faced both seat and wedge / disc to prevent seizing and galling is available.

End Flange Dimensions : ASME B16.5

Butt Weld End Dimensions : ASME B16.25

End to End Dimensions :

– Flanged – ASME B16.10

– Butt Weld – Cast Valves: ASME B16.10

– Forged Valves: Makers Standard

– Screwed & Socket – Makers standard.

Helium Leak Test : Performed for each bellows assembly using helium detector with sensitivity of 10 cc/sec.

Bellows Material : SS321, Inconel 625, Hastelloy, Monel etc…

Hydroformed Multiply Bellows : Minimum of two plies.

Soft Seat Insert on Globe Valves : Soft seat option is available for gas or vacuum service.

Impact Handwheel : Globe Valves fi tted with impact handwheels which may be used to give e ffectively 3 ~ 10 times higher closing force.

Bellows Design Parameters and Testing

SWI Valve Company Ltd. is committed to manufacturing product which exceeds industry standards. Their Bellows Seal Valves carry an exclusive SWI 5 year warranty against defects in material and workmanship.

SWI Bellows Seal Valves are available with a variety of unique features. Their API 602 line is manufactured in Classes 150, 300, 600, 800 and 1500 with SS316 stem and wedge / disc Stellite 6 hardfaced. Their API600 line is available in Classes 150, 300, 600, 900 and 1500. Class 150 valves are manufactured with round bonnet permitting a fully enclosed spiral wound bonnet gasket with superior sealing capability over at bonnet gasket.

All SWI Bellows Seal valves are manufactured with SS321 or Inconel 625 hydroformed multi-ply bellows, welded to the stem and bonnet, creating a hermetic seal.

Applications and Reliability

The use of bellows seal valves has always been considered as the safest and most reliable method / sealing technology for containment of toxic and aggressive fluids whilst providing operators and the environment the highest levels of assurance over any other sealing method.

SWI bellows seal valves have been designed to safeguard and increase the durability of a packed stem seal valve with the addition of a reliable multi-ply metallic bellows sealed stem design which hermetically seals the moving stem.

A standard packed gate or globe valve has a compression packing sealing system on the stem along with a full open shut-o metal to metal back seat between the stem and body.

The addition of a bellows seal is the primary stem seal of the bellows seal valve, but includes the secondary packing and back seat in the design.

SWI Bellows seal valves reduce fugitive emissions of toxic, lethal, or regulated fl uids/gases, minimize maintenance, reduce life cycle costs, and optimize productivity in process plants. This includes steam, cryogenic, and vacuum systems. Optionally, in order to monitor the bellows and packing performance, the valve can be manufactured with a leak detection port in the Bonnet in order to access the cavity between the bellows and the packing. The detection port may be used for leak testing purposes, as well as in line leak detection monitoring.

Request a Quote