High Integrity Floating SWI Ball Valves

Key Features

- Design, manufacture and materials conform to the essential requirements of ISO 17292, ISO 14313, API 608, API 6D, ASME B16.34, ASME VIII and Directives PED 97/23/EC and ATEX 94/9/EC.

- Certified firesafe in accordance with API 607 6 thEdition / ISO 10497.

- Anti-static design (10Ώ under 12 Volt).

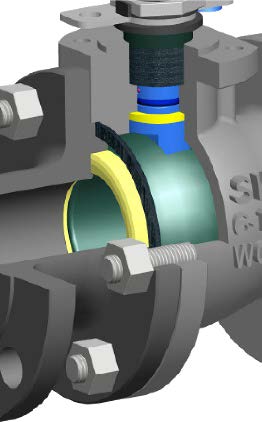

- Positive engagement and alignment of 2 piece bolted body providing ‘Gap Free’ connection.

- Fully contained body gasket, graphite seal is protected from working fluid by primary elastomeric seal for soft seated.

- Body wall thickness exceeds minimum requirements of ASME B16.34 or ISO 17292.

- Full and reduced bore, soft and metal seated designs available.

- Floating ball design for superior bi-directional shut off across a wide range of pressures.

- Internally assembled blow-out proof stem.

- Superior High Integrity live loaded stem sealing system, double seal before & after fire condition.

- Suitable for high vacuum service and technically Emission Free as standard.

- Self adjusting seat design for effective shut-off across a wide range of pressures minimizing operational torque.

- Bolted construction for ease of on-site maintenance.

- Independent stop plate from handlever secured to stem even if lever is removed.

- 316 stainless steel corrosion resistant trim as standard for effective service life.

- Cavity pressure relief to high pressure side in the event of thermal expansion of trapped fluid.

- Positive direct pressure relief to upstream side available via vented ball for high volatility duty.

- ISO 5211 / EN 15081 top works as standard for 2” and above. Modular design, easily adapted for low temperature & cryogenic service or fugitive emission leak detection.

- Testing and marking to API 598 / API 6D and PED (as required).

- Available with gearbox, pneumatic, hydraulic or electric actuators.

Bolted Construction:

Seat Design:

Standard valves utilise Reinforced PTFE seats for maximum chemical compatibility and are designed to FLEX ensuring positive sealing performance across a wide pressure range whilst providing controlled operational torque and cavity relief capability.

Reliable sealing is enhanced via precise pre-compression of the ball between the two flexing seat rings allowing the ball to float along the valve axis providing bubble tight and bi-directional performance.

Slots are incorporated in the external diameter of the R-PTFE seat rings to aid pressure equalization between the high pressure side and the valve cavity thus minimizing the load on the downstream seat rings and optimising the operating torque.

Support and containment of the seat rings within the valve body provides enhanced pressure temperature resistance whilst maintaining the flexing ability under load.

Certified Fire Tested:

Should the valve seat rings be destroyed by the effects of fire, the ball will drift to the low pressure side to form a metal to metal seal on the integral secondary metal seat within the valve body. SWI ball valves have been fire tested and certified to be in accordance with recognized international standards such as API 607 6th Edition, ISO 10497 and API 6FA.

High Integrity Top Entry Ball Valves

Key Features

- Design, manufacture and materials conform to the essential requirements of API 6D, ISO 14313, ASME B16.34, ASME VIII and Directives PED 97/23/EC and ATEX 94/9/EC.

- Certifi ed resafe in accordance with API 607 6th Edition / ISO 10497.

- Anti-static design (10 under 12 Volt).

- Fully contained cover gasket, graphite seal is protected from the working uid by primary elastomeric seal for soft seated.

- Body wall thickness exceeds the minimum requirements of ASME B16.34.

- Full and reduced bore designs available.

- Trunnion supported ball design for superior bi-directional shut o ff performance across a wide range of pressures.

- Single piece body TOP ENTRY construction for in-line and on-site maintenance.

- Internally assembled blow-out proof stem design.

- Bottom entry stem shouldered directly to the body cover and not to any other intermediate bolted part.

- Standard valve features High integrity stem sealing system in compliance with ISO 15848 Class AH & API 622 suitable for high vacuum service and technically emission free.

- In line maintainable stem sealing system.

- Replaceable without the need for valve disassembly or removal of stem.

- Bi-directional, double block & bleed design allowing the venting and draining of the body in the open & closed position.

- Pressure and spring assisted seat design is of the single piston eff ect as standard. Double piston e ffect available.

- Positive cavity relief via single piston e ffect spring loaded seat design, relief is always to the low pressure side.

- Large guided stem (bearings) with hardness control between parts to minimize operational torques.

- Positive seat sealing at high and low diff erential pressures.

- Emergency sealant injection provision to seat and stem seal is available.

- Metal seated designs for CRITICAL or SEVERE service applications.

- Low and high temperature service designs available.

- Testing and marking to API 6D & PED (as required).

- Available with pneumatic, hydraulic or electric actuators.

SWI’s range of Top Entry trunnion mounted ball valve design incorporates some of the most advanced features, including many major Owner & Operating Company specifi cation preferences, whilst fully conforming to the design requirements of ISO 14313 / API 6D & ASME B16.34 codes.

Trunnion mounted design provides reliable bi-directional sealing through spring and pressure assisted seats. The rigidly supported fixed ball via large bearings housed within the body and body cover has two independent spring assisted seat rings which are free to move along the valve axis providing bubble tight and bi-directional sealing capability. The seal is formed by the seat ring assembly being spring loaded & pressure energized against the ball as a result of the piston eff ect created by the fl uid pressure.

At low pressures, the sealing is maintained by the force provided by the seat springs. All these design features contribute towards the valves capability to provide the highest levels of performance and reliability, whilst ensuring repeatable shut o , positive sealing of all external leak paths and a high degree of safety for both plant and personnel.

Top Entry SWI ball valves are available in a wide range of materials and configurations to meet your specific requirements. Some options available include:

- Local weld overlay with corrosion resistant material to critical seal areas.

- Sealant injection to seat and / or stem area.

- Metal seated or primary metal seat with secondary soft insert.

- Transition pup pipes for weld end valves & designs suitable for pigging.

- Drain and Vent Connections with thread protection or valved (Gate / Ball…..) vent & drain valve fitted.

- Pneumatic, Electric or Hydraulic Automation.

- Emergency Shut Down applications.

- Extended bonnets for low or high temperature service.

- Extended stem for underground (buried ) installation.

- Locking & interlocking facilities.

Trunnion Mounted and High Pressure Ball Valves

Key Features

- Design, manufacture and materials conform to the essential requirements of API 6D, ISO 14313, ASME B16.34, ASME VIII and Directives PED 97/23/EC and ATEX 94/9/EC.

- Certified firesafe in accordance with API 607 6 th Edition / ISO 10497.

- Anti-static design (10Ώ under 12 Volt).

- Fully contained body gasket, graphite seal is protected from the working fluid by primary elastomeric seal for soft seated.

- Body wall thickness exceeds the minimum requirements of ASME B16.34.

- Full and reduced bore soft and metal seated designs available.

- Trunnion supported ball design for superior bi-directional shut off performance across a wide range of pressures.

- 2 or 3 piece bolted body construction for ease of on-site maintenance.

- Internally assembled blow-out proof stem design. Bottom entry stem shouldered directly to the body and not to any other intermediate part bolted to the valve.

- High integrity stem sealing system as standard, suitable for high vacuum service and technically emission free.

- In line maintainable stem sealing system. Replaceable without the need for valve disassembly or removal from the pipeline.

- Bi-directional, double block & bleed design allowing the venting and draining of the body in the open & closed position.

- Pressure and spring assisted seat design is of the single piston effect as standard.

- Positive cavity relief via spring loaded seat design to the low pressure side.

- Guided stem (bearings) with hardness control between parts to minimize operational torques.

- Positive seat sealing at high and low differential pressures.

- Emergency sealant injection provision to seat and stem seal is available.

- Metal seated designs for CRITICAL or SEVERE service applications.

- Low temperature and cryogenic service designs available.

- Testing and marking to API 6D & PED (when required).

- Available with pneumatic, hydraulic or electric actuators.

SWI’s range of trunnion mounted and high pressure ball valve designs incorporate some of the most advanced features, including many major Owner & Operating Company specification preferences, whilst fully conforming to the design requirements of ISO 14313 /API 6D & ASME B16.34 codes.

Trunnion mounted designs provide reliable sealing at the upstream or high pressure side through spring and pressure assisted seats. The supported fixed ball has two independent spring assisted seat rings which are free to move along the valve axis providing bubble tight and bi-directional sealing capability. The seal is formed by the seat ring assembly being spring loaded & pressure energised against the ball as a result of the piston effect created by the fluid pressure. At low pressures, the sealing is maintained by the force provided by the seat springs.

All these design features contribute towards the valves capability to provide the highest levels of performance and reliability, whilst ensuring repeatable shut off, positive sealing of all external leak paths and a high degree of safety for both plant and personnel.

Trunnion mounted SWI ball valves are available in a wide range of materials and configurations to meet your specific requirements. Some options available include:

- Full internal cladding with corrosion resistant material.

- Sealant injection to seat and / or stem area.

- Metal seats & special coatings.

- Designs suitable for Pigging

- Combined Drain and Vent Connections with thread protection.

- Pneumatic, Electric or Hydraulic Automation.

- Emergency Shut Down applications.

- Extended bonnets for low temperature or cryogenic service.

- Underground (buried ) service designs

- Locking & Interlocking Facilities.