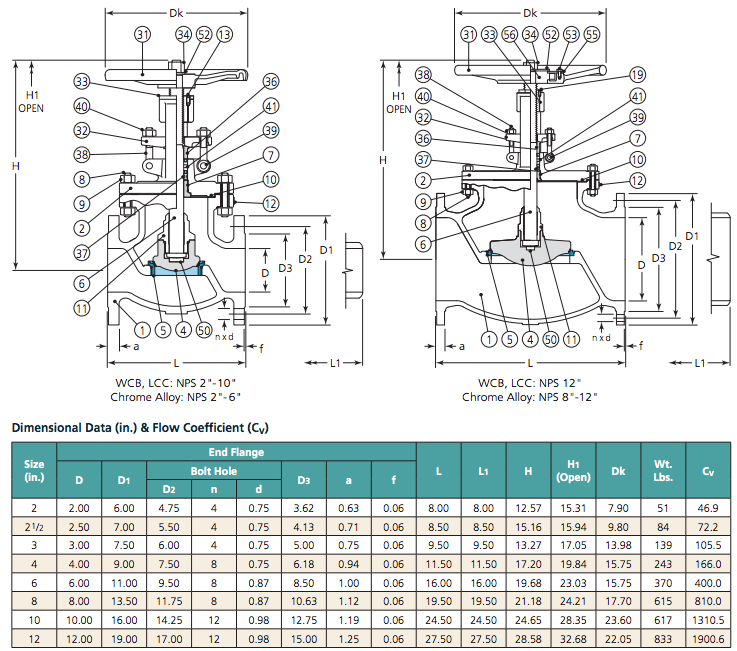

DSI Globe Valves – Cast Steel

DSI Gate Valves – Pressure Seal

DSI Pressure Seal Valves are intended for high pressure, high temperature applications in all types of fluid except where severe coking is a factor. The design and material selections provide excellent service in steam-generation stations, industrial chemical plants and thermal power plants.

Most pressure seal valves are offered in Cast Steel and Forged Steel body designs. These options make the DSI Pressure Seal product line an excellent choice for users with various application requirements. These pressure seal valves provide the most efficient flow passage and sealing features available, resulting in significant weight savings, easy installation and in-line maintenance.

Standard Construction Features:

Body: Flow areas are specifically designed for minimum turbulence and pressure drop.

Bonnet Ample stuffing box area, Stellite® stem guide surface and back seat shoulder for accurate guiding of the stem and back seat.

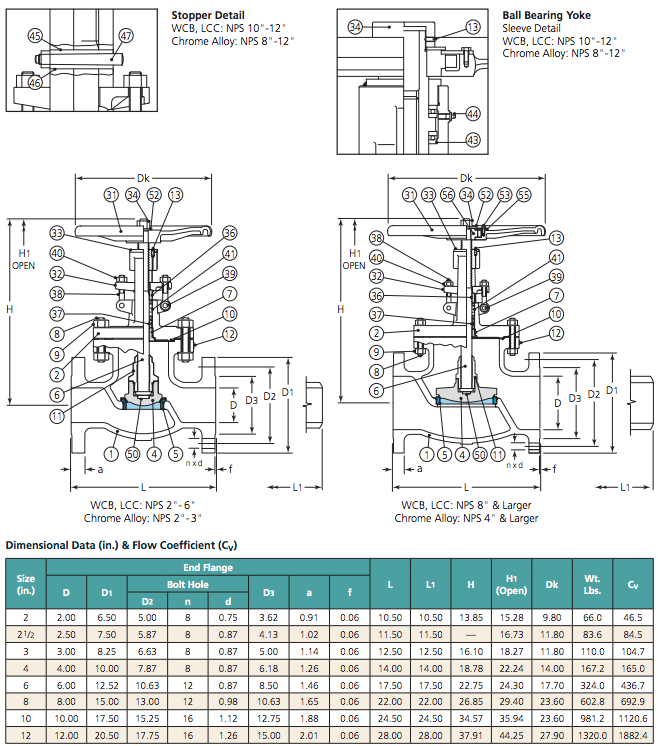

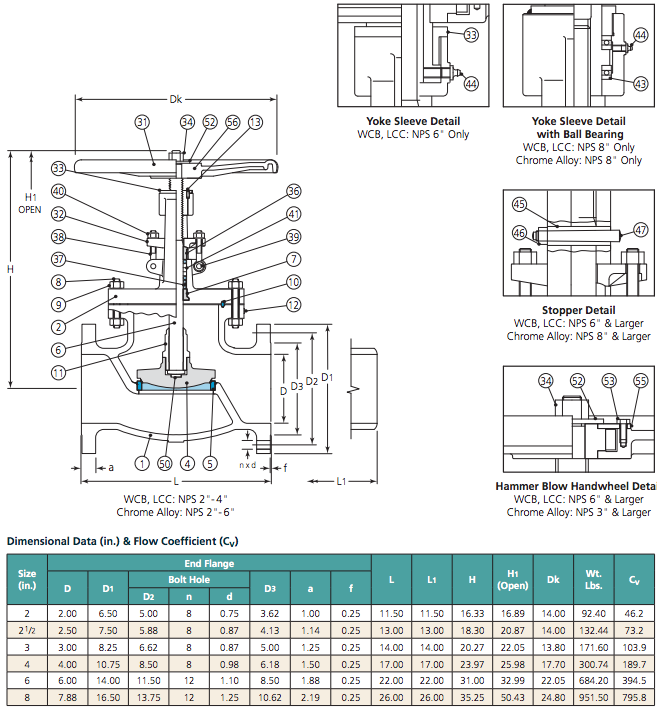

Ball Bearing-type Yoke Sleeve Large, high-pressure valves can require a tremendous amount of torque to open and close. By utilizing ball bearings in the yoke sleeve the operating torques of these difficult-to-operate valves are reduced by as much as 50 percent.

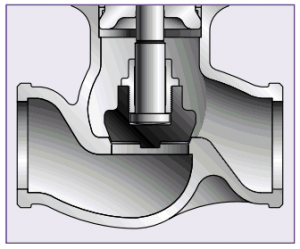

Straight and Y-Pattern Seating Design (Globe Valves) All DSI® globe valves utilize the same seating design which consist of guided disc which seals fully with the seat to provide an effective tight seal. Seating surfaces are hardfaced with Stellite®6to increase the cycle life. All DSI® globe valves are unidirectional. A non-return stop check feature is available on request.

Special Features of All DSI Pressure Seal Globe Valves

Packing Adjustment: All gate and globe valves are provided with a two-piece packing gland to minimize the possibility of scoring the stem if the gland is tightened unevenly. Eyebolts remain fastened to the bonnet. The eyebolts swing out of the way to simplify packing replacement, and are oriented so they can be adjusted from one side of the valve.

Deep Stuffing Boxes: Deep stuffing boxes are standard on gate and globe valves. The design provides extra packing for a more reliable stem seal, or sufficient depth for packing with an optional lantern ring in the middle. When equipped with a lantern ring, a tapped and plugged hole is provided; when specified, it can be fitted with an injection fitting.

Pressure Seal Design: The segmental thrust ring absorbs all the thrust applied by internal pressure. A hardened Stainless Steel protective ring prevents deformation of the top surface of the soft steel, 304 Stainless or 316 Stainless with a high density graphite gasket. The gasket can be removed freely without damaging the seal- ing surface of the body.

Request a Quote